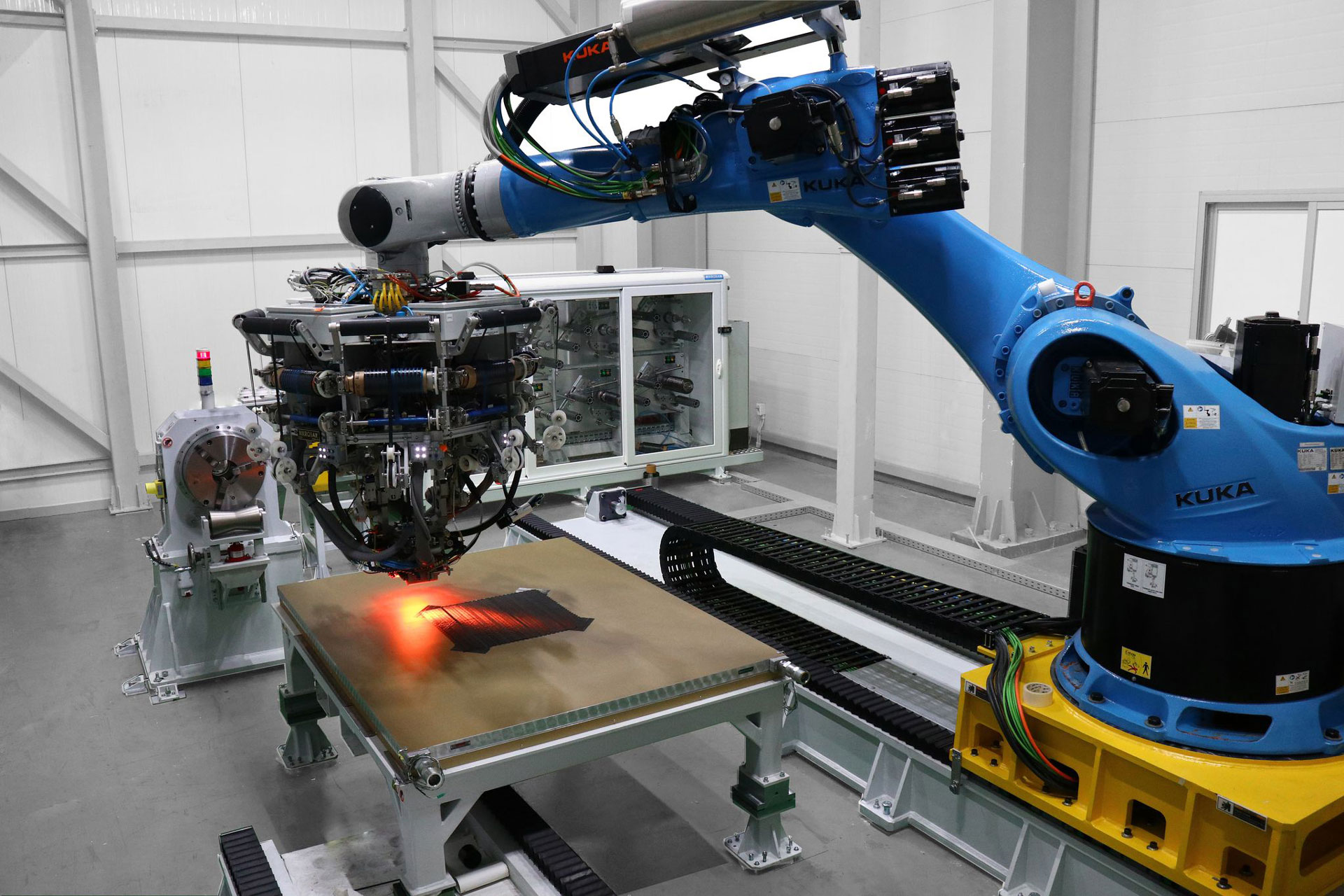

Libra AFP/ATL

Starter Production Units and Advanced R&D - MIKROSAM

Starter production and advanced R&D cell featuring a KUKA Quantec-class robot on high- or low-rail gantry, interchangeable AFP head with 8, 16+ tows, and ATL capability for 50–150 mm tapes with automated head exchange.

Tow Configuration:

AFP processing: 4, 8, 16, or expanded tow arrangements

Tow widths: 6.35mm (1/4"), 12.7mm (1/2"), or 25.4mm (1")

Single-tape AFP capability: 6.35mm (1/4") to 50.8mm (2") tape widths

Material Compatibility:

Thermoset, thermoplastic, and dry fiber processing

Performance Parameters:

Maximum layup rate: 80 m/min*

Cut-and-restart precision: ±2.5mm*

Course placement tolerance: -0/+2.5mm*

Minimum cut/restart spacing: ≤10mm*

Minimum course length: 120mm*

Heating Systems:

Infrared heating: 1kW and higher

Laser heating: 3, 4, 6kW or greater capacity

Integrated infrared and visual process monitoring cameras

*Performance dependent on material properties, cell configuration, controller specifications, tooling geometry, and processing speed for production reliability

Tape Processing Capabilities:

ATL processing: up to 300mm (12") wide tape configurations

Available widths: 50mm (2"), 75mm (3"), 150mm (6"), 300mm (12")

Cutting Technology:

Dual ultrasonic knife contour cutting system

Pre-layup defect detection capabilities

Proprietary ATL head design

Platform Configurations:

Robotic, high-rail gantry, low-rail portal, and column-based architectures

Optional environmental enclosure systems

Scale Options:

Laboratory-scale and industrial production equipment for serial manufacturing

Integration Capabilities:

Multi-function work-cell integration for enhanced productivity and ROI optimization

Custom design solutions and specialized functionality available

Motion Control:

Robotic linear and tool rotational axis systems

Integration Features:

Barcode reading systems with factory automation integration

Laser projection and inline inspection capabilities

Ultrasonic trimming functionality